Benefits of Formability Analysis

Formability analysis is a powerful tool that transforms how you develop and optimize sheet metal forming processes. Here's what our simulation solutions can help you accomplish:

Multi-Stage Formability Analysis

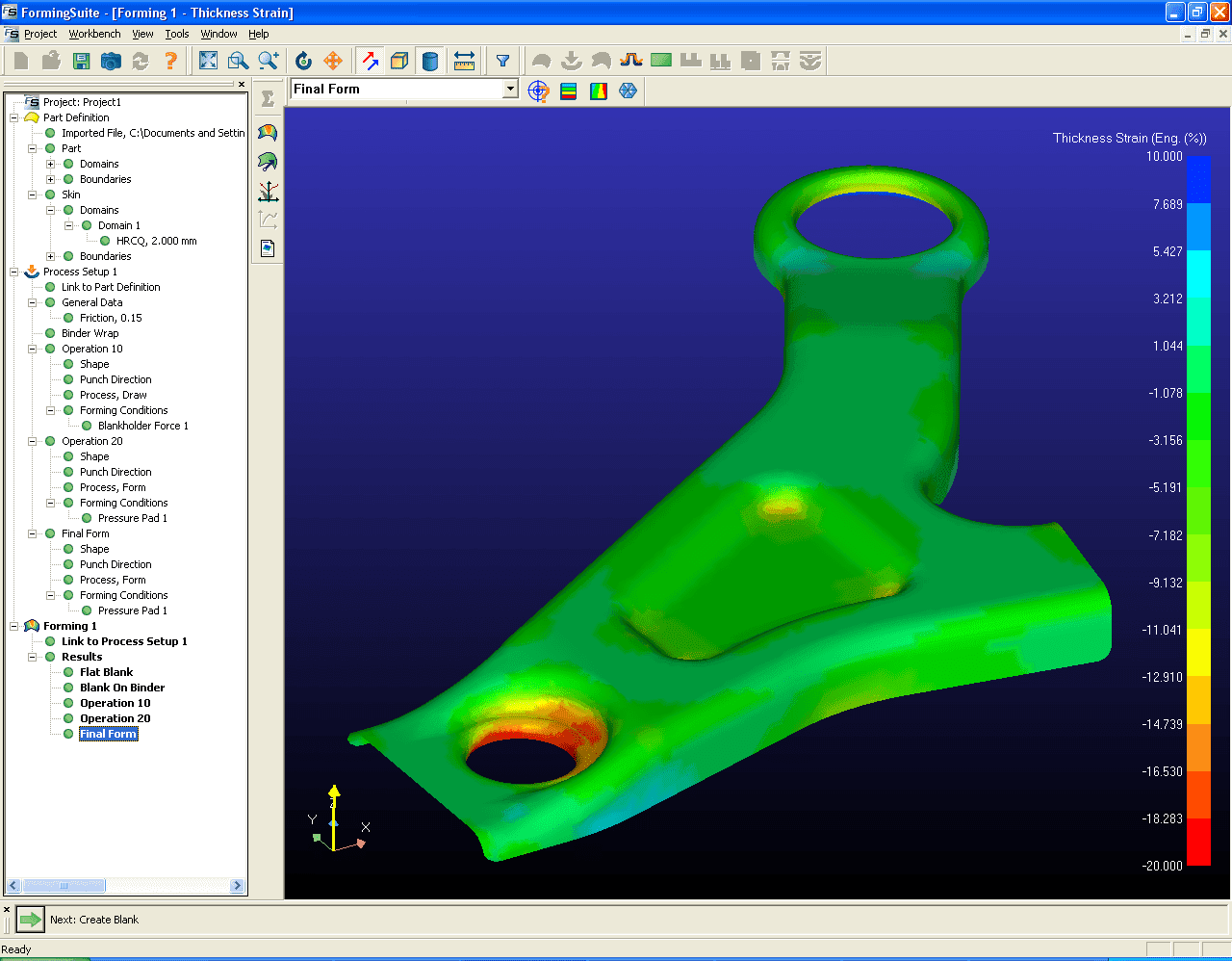

Advanced simulation of complex forming operations to predict material behavior and potential defects across multiple stages of the forming process.

- Strain distribution analysis

- Forming limit diagram (FLD) analysis

- Thickness reduction prediction

- Springback analysis

- Material flow optimization

Advanced Analysis Technologies

Our engineering team utilizes state-of-the-art simulation software to provide comprehensive insights into sheet metal forming processes. We deliver practical solutions to complex forming challenges through advanced analysis techniques.

- Strain-based and stress-based forming limit analysis

- Advanced material models for accurate behavior prediction

- High-fidelity simulation with non-linear material properties

- Springback prediction and compensation strategies

Our Formability Analysis Approach

We follow a structured, data-driven methodology to ensure accurate, actionable results that directly improve your manufacturing processes:

- 1

Process Assessment

Comprehensive evaluation of part design, material properties, and process requirements

- 2

Digital Simulation

High-fidelity modeling of forming processes using advanced simulation techniques

- 3

Analysis & Identification

Detailed analysis of simulation results to identify potential issues and improvement opportunities

- 4

Optimization & Implementation

Data-driven recommendations and iterative refinement for optimal manufacturing results